Features

Laser Tube Cutting for Various Shapes

- Round Tube

- Square Tube

- Rectangular Tube

- Oval Tubes

- L-shaped profiles

- C-shaped profiles

- Mild Steel, Stainless Steel, and Aluminium

Automation Working Processes:

- Automatic Tube Bundle Loading

- Automatic Material Alignment

- Automatic Feeding and Rotation

- Fiber Laser Tube Cutting

- Unloading

Typical Tube Laser Cutting Processes:

1. Straight + Angle Cutting

2. Slotting

3. Marking

4. Notching

5. Hole Making

Nesting

Seam Detector_Tubes and Profiles (Optional)

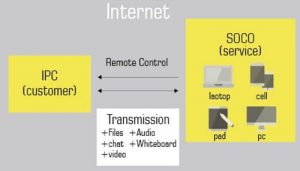

SOCO IRMS (Internet Remote Monitoring System)

- True Remote Access from Anywhere: Connect to i2 Controls using any mobile device, computer or laptop

(Windows, iOS or Android) from any location with Internet Access. - Actual Screen + Real Time Access to laser tube cutting file,

with full ability to see, edit and troubleshoot all user created programs. - Live Remote Connection to Manufacturer and Service Support with Ability to Call + Message + Record at the same time.

- Maintenance Scheduling Systems:

– Advanced Table with Detailed Maintenance Items;

– Customizable Alarms for Daily, Weekly, Quarterly, and Yearly Items;

– Maintenance Records connected to User Login;

- Built-in Self-diagnostics + Error messages display + I/O Tables with Descriptions

- Webcam Ready for Video Monitoring (Optional)