Features

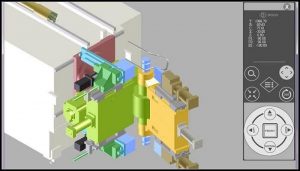

Equipped with 7-10 electric CNC axis, 2+2 bending stacks and uses SOCO’s unique DGT technology (Direct Gear Transmission).

- Left + Right bending capabilities in the same cycle

- All Electric ( 7~10 Electric Servo Control Axis )

- DGT technology – Gear Transmission Bending for Highest Speed and Accuracy

- Easy Programming–Setup a part in the same way as a single directional bend

Automatic Tube Bender Cell

SOCO’s Tube Bender can be integrated with Automatic Loaders (AF, AFM, Robots) and Automatic Unloaders (AUL , ROBOTS) for full automation. This tube benders series can offer one of highest performance solutions available in the market.

Advanced DGT

SOCO’s unique DGT technology (Direct Gear Transmission) is the worldwide patented bending system that brings you the most efficient and stable bending process, offering the highest accuracy and repeatability in draw and roll bending.

SOCO i2 Controls, Software and Operation Interface

- Automatic springback compensation

- Recapturing function for short lengths

- Windows platform

- Self-diagnostics + Error messages display

- Connection and Auto compensation to CMM systems

- Overmode + Teach Mode

- Live remote monitoring by internet

- Remote troubleshooting

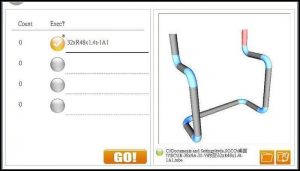

- Bending interference and collision simulator

- SOCO CAD Reader

- VRM: Variable Radius Measuring System

3D Display and Rotation of Parts

- XYZ and YBC coordinates conversion

- Mirroring and image reversal of parts

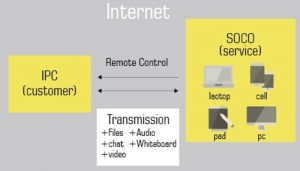

SOCO IRMS (Internet Remote Monitoring System)

- True Remote Access from Anywhere: Connect to i2 Controls using any mobile device, computer or laptop (Windows, iOS or Android) from any location with Internet Access.

- Actual Screen + Real Time Access to tube bending file, with full ability to see, edit and troubleshoot all user created programs.

- Live Remote Connection to Manufacturer and Service Support with Ability to Call + Message + Record at the same time.

- Maintenance Scheduling Systems

- Advanced Table with Detailed Maintenance Items

- Customizable Alarms for Daily, Weekly, Quarterly and Yearly Items

- Maintenance Records connected to User Login

5. Built-in Self-diagnostics + Error messages

display + I/O Tables with Descriptions

6. Webcam Ready for Video Monitoring

(Optional)