Features

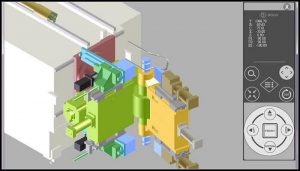

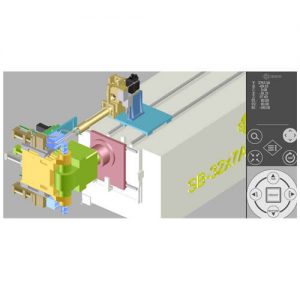

Tube Bender for Car Trunk Hinge

Tube Bender for Car Trunk Hinge

Advanced DGT. Most efficient and stable bending process.

- Chain free transmission

- Built-in gearbox with direct connection to electric servo

- Highest transmission performance (90%+ efficiency)

- High bending accuracy ( +- 0.05° ~ +-0.1° )

- Maximum Working Area = Minimal Interference

- Elongated neck for superior clearance

- Side carriage and bending head

SOCO i2 Controls, Software and Operation Interface

- Automatic spring back compensation

- Recapturing function for short lengths

- XYZ and YBC coordinates conversion

- 3D display and rotation of bending parts

- Mirroring and image reversal of parts

- Windows platform

- Self-diagnostics + Error messages display

- Connection and auto tube bending compensation to CMM systems

- Overmode + Teach Mode

- Live remote monitoring by internet

- Remote troubleshooting

- Connection though PC, Mobile Phone and Tablet

- Tube bending interference and collision simulator

- SOCO CAD Reader

- VRM : Variable Radius Measuring System

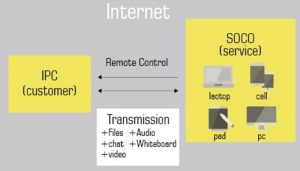

SOCO IRMS (Internet Remote Monitoring System)

- True Remote Access from Anywhere: Connect to i2 Controls using any mobile device, computer or laptop (Windows, iOS or Android) from any location with Internet Access.

- Actual Screen + Real Time Access to tube bending file, with full ability to see, edit and troubleshoot all user created programs.

- Live Remote Connection to Manufacturer and Service Support with Ability to Call + Message + Record at the same time.

- Maintenance Scheduling Systems

- Advanced Table with Detailed Maintenance Items

- Customizable Alarms for Daily, Weekly, Quarterly and Yearly Items

- Maintenance Records connected to User Login

5. Built-in Self-diagnostics + Error messages

display + I/O Tables with Descriptions

6. Webcam Ready for Video Monitoring

(Optional)

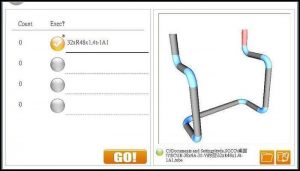

3D Display and Rotation of Tube Bending Parts

- XYZ and YBC coordinates conversion

- Mirroring and image reversal of parts